Environmental Geomembrane

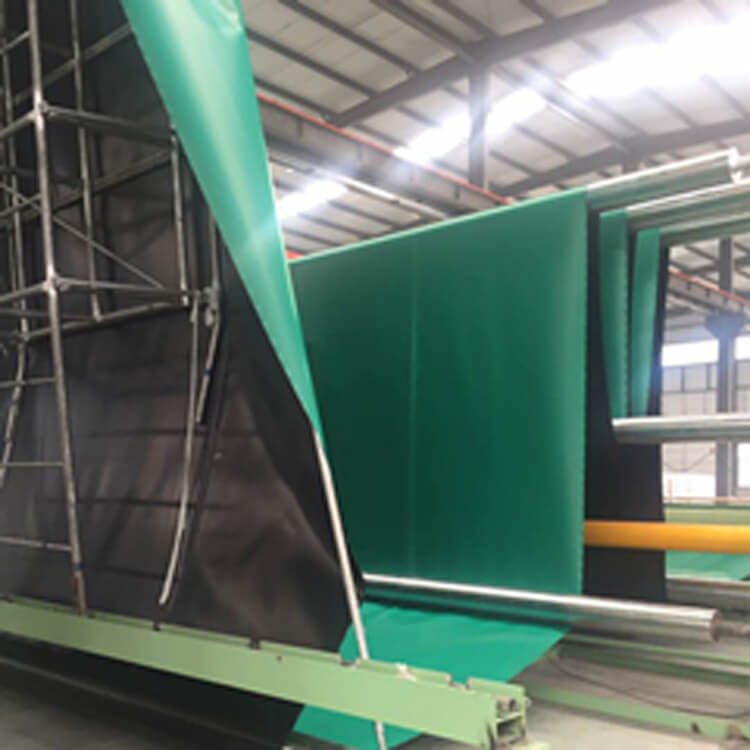

The production methods of HDPE geomembrane Environmental high quality environmental geomembrane are blow molding and calendaring. The popular production method is blow molding, we have advanced production line and max-width can be 10m, the max thickness for blowing is 2.5mm.

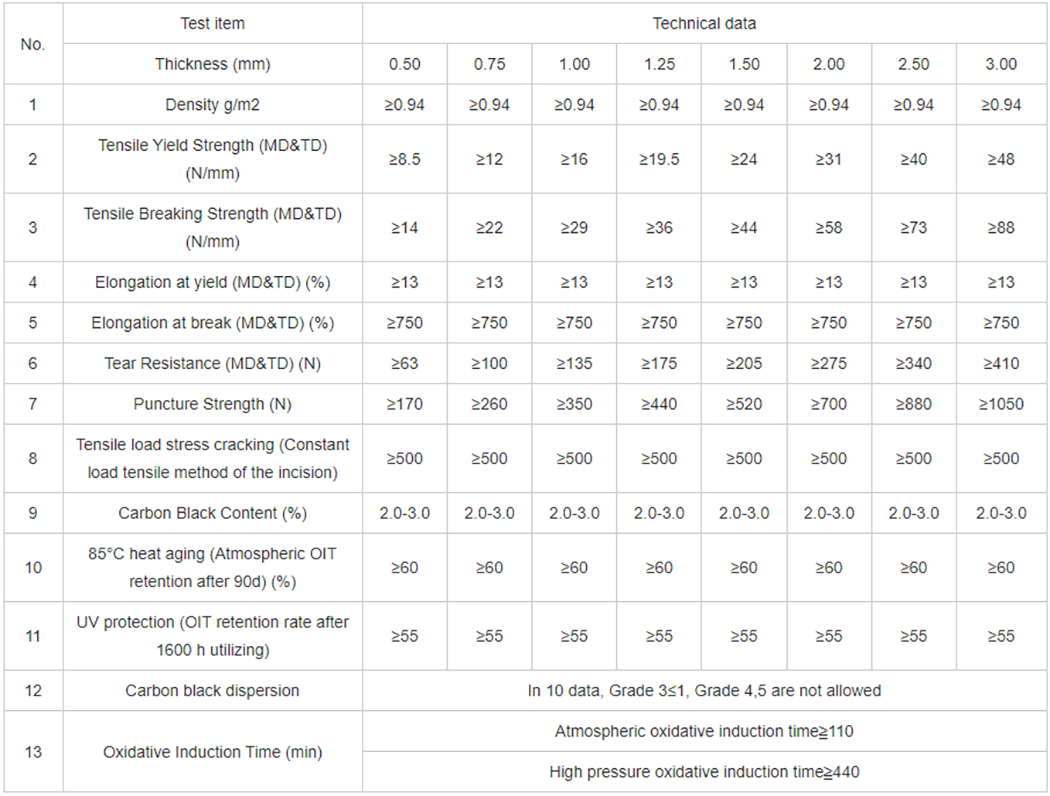

The environmental geomembrane strictly produced according to the American standard GRI GM-13, and test by the ASTM method. So, it is a high-grade virgin HDPE environmental geomembrane, with very good UV resistance, aging resistance, corrosion resistance, and long service time.

1. Environmental geomembrane has High physical and mechanical indexes: the tensile strength can reach more than 27MPa; Elongation at break can reach more than 800 percent; the right-angle tear strength can reach more than 150N/mm.

2. Environmental geomembrane has Good chemical stability, widely used in sewage treatment, chemical reaction tank, and landfill. Resistance to high and low temperature, asphalt, oil and tar, acid, alkali, salt, and more than 80 kinds of strong acid and alkali chemical medium corrosion.

3. Environmental geomembrane has a High anti-seepage coefficient,has an incomparable anti-seepage effect compared with ordinary waterproof materials, and the water vapor seepage system K<=1.0*10-13g. Cm /c cm2.s. a.

4.Environmental geomembrane is friendly to the environment. It uses environmental protection material, the impervious principle is a common physics change, does not produce any harmful material, it is the best choice of environmental protection, breed, and drinkable pool.

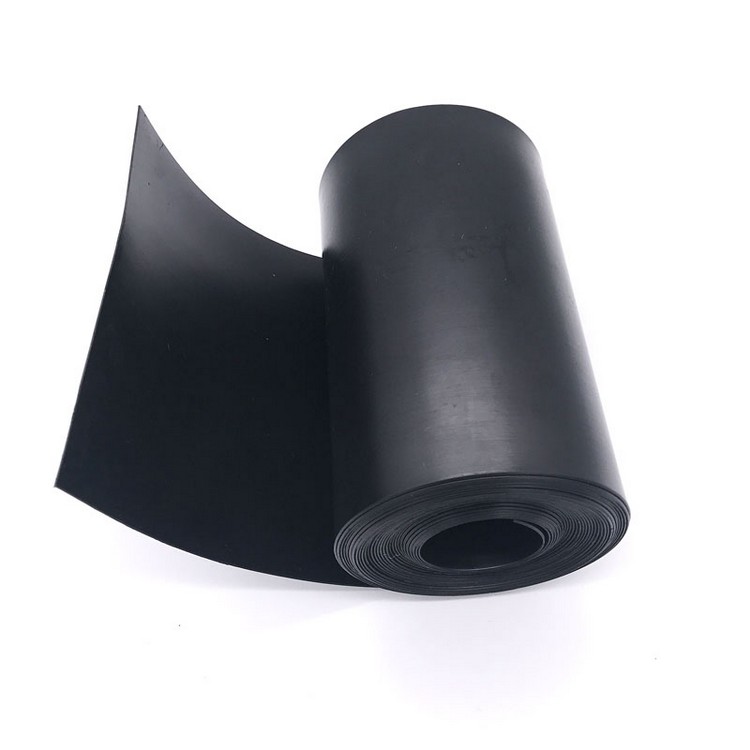

Thickness: 0.1mm-4mm

Width: 1-10m

Length: 20-200m (customized)

Color: black/white/transparent/green/blue/customized

1. Salt Industry (brine pool coversalt , salt pool geomembrane,crystallization pool, salt geomembrane)

2. Hygiene and environmental protection (such as waste toxic and hazardous substances, treatment plants, sewage treatment landfills, buildings, dangerous goods warehouses, blasting waste, etc.)

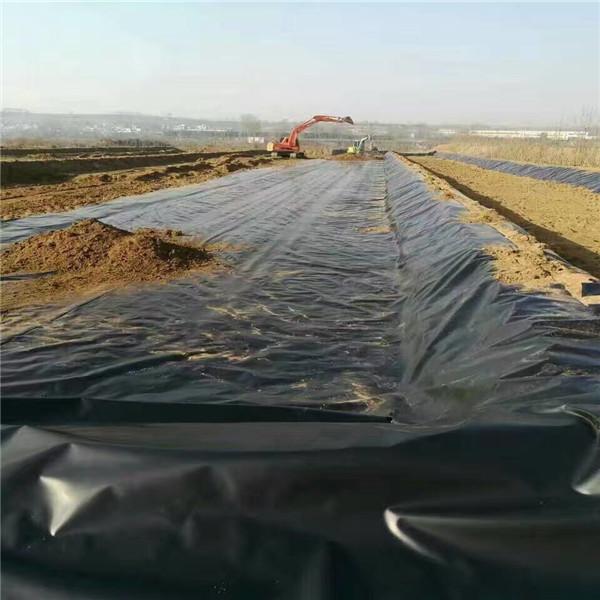

3. Agriculture (anti-seepage of reservoirs, irrigation systems, reservoir cisterns, drinking ponds)

4. Aquaculture (sea cucumber circle slope protection, shrimp pond lining, fish pond, etc.)

5. Municipal engineering (roof storage tank, underground engineering of buildings and subway, lining of sewage pipes, seepage prevention of roof garden, etc.)

6. Water conservancy (such as plugging, anti-seepage, vertical core wall of channel anti-seepage, environmental protection geomembrane, reinforcement, slope protection, etc.

7. Petrochemical industry (sedimentation tank lining, gas station storage tank anti-seepage, oil refinery, secondary lining, chemical reaction tank, chemical plant, wholesale environmental protection geomembrane, etc.)

8. Gardens (ponds, artificial lakes, golf course pond linings, slope protection, etc.)

9. Mining industry (heap leach tank, washing tank, dissolution tank, ash yard, storage yard, sedimentation tank, tailings pond and other substrate impermeability)