HDPE Liner

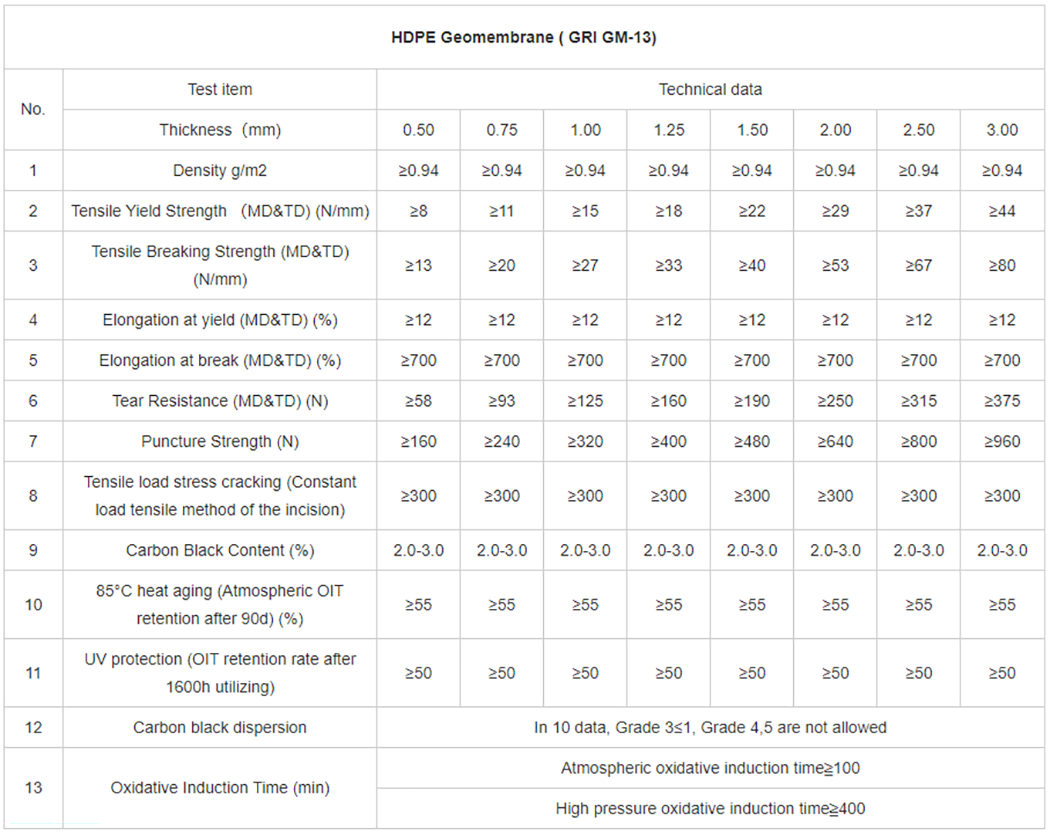

1. HDPE Liner has complete width and thickness specifications.

2. HDPE Liner has an excellent anti-seepage effect.

3. HDPE Liner has excellent environmental stress cracking resistance and chemical corrosion resistance.

4. HDPE Liner has excellent chemical corrosion resistance.

5. HDPE Liner has a large service temperature range and long service life.

Thickness: 0.1mm-6mm

Width: 1-10m

Length: 20-200m (customized)

Color: black/white/transparent/green/blue/customized

1. Environmental protection and sanitation (e.g. landfill, sewage treatment, poisonous and harmful substance treatment plant, dangerous goods warehouse, industrial waste, construction, and blasting waste, etc.)

2. Water conservancy (such as seepage prevention, leak plugging, reinforcement, seepage prevention vertical core wall of canals, slope protection, etc.)

3. Municipal works (subway, underground works of buildings and roof cisterns, seepage prevention of roof gardens, the lining of sewage pipes, etc.)

4. Garden (artificial lake, pond, golf course pond bottom lining, slope protection, etc.)

5. Petrochemical (chemical plant, refinery, gas station tank seepage control, chemical reaction tank, sedimentation tank lining, secondary lining, etc.)

6. Mining industry (bottom lining impermeability of washing pond, heap leaching pond, ash yard, dissolution pond, sedimentation pond, heap yard, tailings pond, etc.)

7. Agriculture (seepage control of reservoirs, drinking ponds, storage ponds, and irrigation systems.)

8. Aquaculture (lining of the fish pond, shrimp pond, slope protection of sea cucumber circle, etc.)

9. Salt industry (salt crystallization pool, brine pool cover, salt geomembrane, salt pool geomembrane.)

Do not drag the HDPE geomembrane during transportation to avoid the HDPE geomembrane being punctured by sharp objects.

1. The longitudinal seams of two adjacent pieces shall not be on a horizontal line, and shall be staggered by more than 1m;

2. Stretch from the bottom to the height, do not pull too tightly, and leave 1.50% of the residual to prevent local subsidence and stretching. Taking into account the actual situation of the project, the sloping land is laid from top to bottom.

3. Install the HDPE liner on the slope first, and then install the bottom;

4. The longitudinal seam is more than 1.5m away from the dam foot and the bent foot, and should be set on the plane;

5. The construction can only be carried out when the wind direction of the working condition is below grade 4;

6. The temperature should generally be above 5 degrees Celsius. The HDPE lining geomembrane should be tightened at low temperature and loose at high temperature.

7. When the slope is laid, the direction of the film should be basically parallel to the maximum slope line.

8. In windy weather, when the wind affects the construction of HDPE lining, the HDPE geomembrane lining to be welded should be pressed firmly with sandbags.

9. When the temperature is too low, the construction shall not be carried out in the weather of strong wind, rain and snow above grade